Kusehlotyeni, kwaye ngeli xesha, iimpazamo zobushushu obuphezulu beiicompressors zomoyarhoqo.Eli nqaku lishwankathela izizathu ezahlukeneyo ezinokwenzeka zobushushu obuphezulu.

1. Inkqubo yecompressor yomoya imfutshane kwioli.

Inqanaba leoli le-oyile kunye ne-gas barrel linokujongwa.Emva kokuvalwa kunye noxinzelelo loxinzelelo, xa ioli yokuthambisa iphumle, inqanaba leoli kufuneka libe phezulu kancinci kunophawu lwenqanaba le-oyile ephezulu (umgca obomvu ongentla).Ngethuba lokusebenza kwezixhobo, inqanaba leoli alikwazi ukuba ngaphantsi komgangatho we-oyile ophantsi (umgca obomvu ongezantsi).Ukuba kufunyenwe ukuba ubungakanani beoyile alanelanga okanye izinga leoli alinakubonwa, misa umatshini ngokukhawuleza kwaye ugcwalise i-refuel.

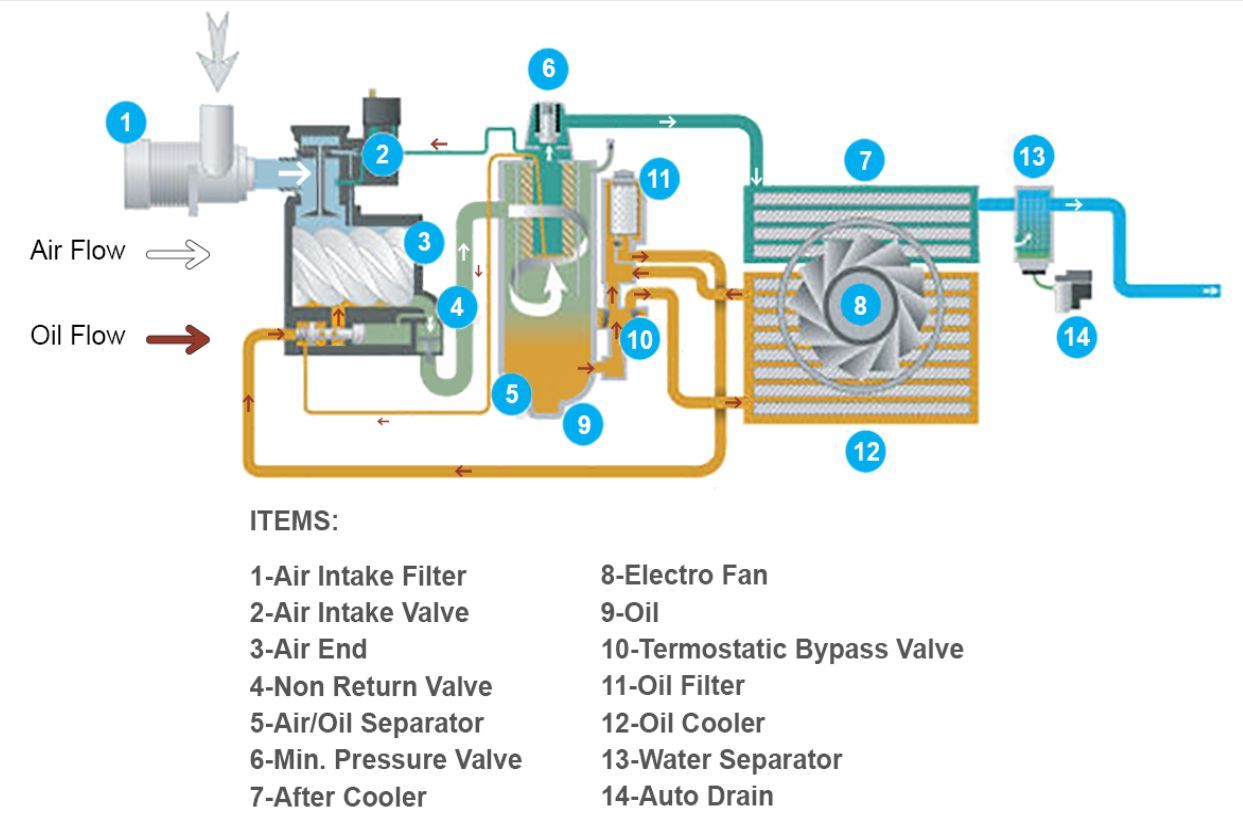

2. Ivalve yokumisa ioyile (ivalve yokusika ioyile) ayisebenzi kakuhle.

Ivalve yokumisa i-oyile ngokuqhelekileyo iyindawo-emibini-yesiqhelo-evaliweyo ivelufa ye-solenoid, evulwa xa iqala kwaye ivalwe xa imiswa, ukuze kuthintelwe i-oyile kwi-oyile kunye nerhasi yomgqomo ukuba ingaqhubeki nokutshiza kwintloko yomatshini kwaye fafaza uphume kwindawo yokungena umoya xa umatshini umisiwe.Ukuba icandelo alivulwanga ngexesha lokulayisha, injini ephambili iya kutshisa ngokukhawuleza ngenxa yokungabikho kweoli, kwaye kwiimeko ezinzima, i-screw assembly iya kutshiswa.

3. Ingxaki yokucoca i-oyile.

A: Ukuba i-oyile yokucoca ivaliwe kwaye ivalve yokudlula ayivulwanga, iumoya compressorioli ayikwazi ukufikelela kwintloko yomatshini, kwaye injini enkulu iya kutshisa ngokukhawuleza ngenxa yokungabikho kweoli.

B: Isihluzo se-oyile sivalekile kwaye izinga lokuhamba liba lincinci.Kukho imeko yokuba i-compressor yomoya ayithathwanga ngokupheleleyo ngubushushu, kwaye ukushisa kwe-compressor yomoya kuphakama ngokukhawuleza ukwenza ukushisa okuphezulu.Enye imeko bubushushu obuphezulu becompressor yomoya emva kokuba icompressor yomoya yothulwe, kuba uxinzelelo lweoyile lwangaphakathi lwecompressor yomoya luphezulu xa icompressor yomoya ilayishiwe, ioyile yecompressor yomoya inokudlula, kunye noxinzelelo lweoyile yomoya. iphantsi emva kokuba icompressor yomoya isothulwe.I-oyile yokucoca i-compressor yomoya inzima, kwaye izinga lokuhamba lincinci kakhulu, elibangela ukushisa okuphezulu kwe-compressor yomoya.

4. Ivalve yokulawula ubushushu (ivalve yokulawula ubushushu) ayisebenzi kakuhle.

I-valve yokulawula i-thermal ifakwe phambi kwe-oyile epholileyo, kwaye umsebenzi wayo kukugcina ukushisa kwentloko yomatshini ngaphezu kwendawo yoxinzelelo lwamazolo.

Umgaqo wayo wokusebenza kukuba ngenxa yeqondo lokushisa eliphantsi kweoli xa uqala, isiphaluka sesebe sokulawula i-thermal sivulwa, isiphaluka esikhulu sivaliwe, kwaye ioli yokuthambisa ifafazwe ngokuthe ngqo kwintloko yomatshini ngaphandle kokupholisa;xa iqondo lokushisa liphakama ngaphezu kwe-40 ° C, i-valve yokulawula i-thermal ivalwe ngokuthe ngcembe, I-oyile ihamba nge-cooler kunye nesebe ngexesha elifanayo;xa iqondo lokushisa liphakama ngaphezu kwe-80 ° C, i-valve ivalwe ngokupheleleyo, kwaye yonke ioli yokuthambisa idlula kwindawo epholileyo kwaye ingena kwintloko yomatshini ukupholisa ioli yokuthambisa ukuya kwinqanaba elikhulu.

Ukuba i-valve yokulawula i-thermal ayiphumelelanga, ioli yokuthambisa ingangena ngokuthe ngqo kwintloko yomatshini ngaphandle kokudlula kwindawo epholileyo, ukwenzela ukuba ukushisa kweoli akukwazi ukuthotywa, okubangelwa ukushisa.

Isizathu esona sizathu sokungaphumeleli kwayo kukuba i-coefficient of elasticity of the two heat-sensitive springs on the spool utshintsho emva kokukhathala, kwaye ayikwazi ukusebenza ngokuqhelekileyo kunye nokutshintsha kweqondo lokushisa;okwesibini kukuba umzimba wevalve unxitywe, i-spool ibambekile okanye isenzo asikho endaweni kwaye ayikwazi ukuvalwa ngokuqhelekileyo.Inokulungiswa okanye itshintshwe ngokufanelekileyo.

5. Isilawuli somthamo wamafutha asiqhelekanga, kwaye umthamo wenaliti yamafutha unokongezwa ngokufanelekileyo ukuba kuyimfuneko.

Umthamo wokutofa kwamafutha uhlengahlengiswe xa isixhobo siphuma kumzi-mveliso, kwaye akufanele sitshintshwe phantsi kweemeko eziqhelekileyo.Le meko kufuneka ibalelwe kwiingxaki zoyilo.

6. Ukuba i-oyile ye-injini idlula ixesha lenkonzo, i-oyile ye-injini iyakonakala.

I-fluidity ye-oyile ye-injini iba yimbi, kwaye ukusebenza kotshintshiselwano lobushushu kuyehla.Ngenxa yoko, ubushushu obuvela entloko yeumoya compressorayikwazi ukususwa ngokupheleleyo, okubangelwa ukushisa okuphezulu kwe-compressor yomoya.

7. Jonga ukuba i-oyile epholileyo isebenza ngesiqhelo.

Kwiimodeli ezipholileyo ngamanzi, unokujonga umahluko weqondo lokushisa phakathi kokungena kunye nemibhobho yokuphuma.Kwiimeko eziqhelekileyo, kufuneka kube ngu-5-8 ° C.Ukuba ingaphantsi kwe-5 ° C, ukunyuswa okanye ukuvaleka kunokwenzeka, okuya kuchaphazela ukusebenza kakuhle kokutshintshisana kobushushu bepholile kwaye kubangele ukutshatyalaliswa kobushushu.Isiphene, ngeli xesha, umtshintshi wobushushu unokususwa kwaye ucocwe.

8. Khangela ukuba iqondo lokushisa lokungena kwamanzi okupholisa liphezulu kakhulu, ukuba uxinzelelo lwamanzi kunye nokuhamba kwamanzi kuqhelekileyo, kwaye ukhangele ukuba ubushushu be-ambient buphezulu kakhulu kwimodeli epholileyo yomoya.

Ubushushu bokungena kwamanzi okupholisa akufuneki budlule kwi-35 ° C, kwaye isantya sokuhamba kufuneka singabi ngaphantsi kwe-90% yesantya sokuhamba esixeliweyo xa uxinzelelo lwamanzi luphakathi kwe-0.3 kunye ne-0.5MPA.

Ubushushu be-ambient akufuneki bube ngaphezulu kwama-40°C.Ukuba ezi mfuno zingentla azikwazi ukufezekiswa, zinokusombululwa ngokufaka iinqaba zokupholisa, ukuphucula umoya wangaphakathi, kunye nokwandisa indawo yegumbi lomatshini.Unokujonga kwakhona ukuba ngaba i-fan yokupholisa isebenza ngokuqhelekileyo, kwaye ukuba kukho nakuphi na ukungaphumeleli, kufuneka ilungiswe okanye itshintshwe.

Ixesha lokuposa: Jun-02-2023