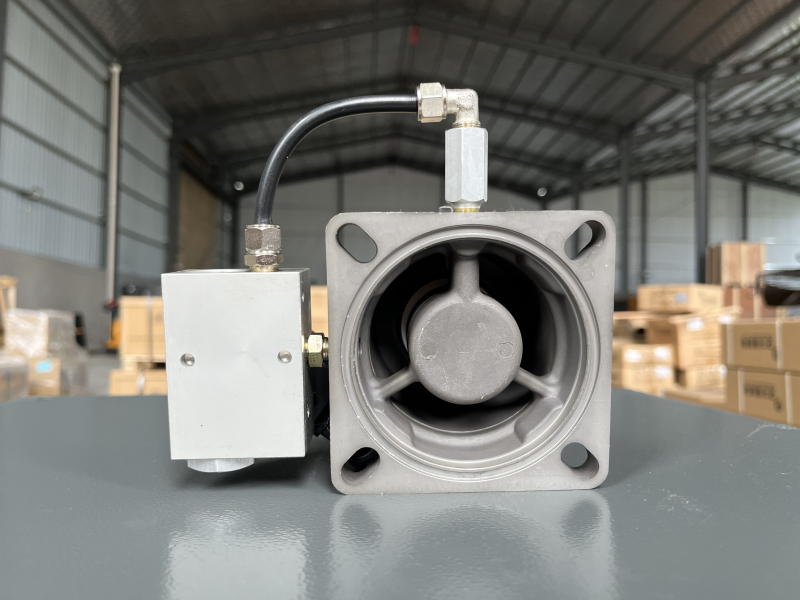

Ivalvu yokungenisa umoya yinxalenye ebalulekileyo yenkqubo ye-screw air compressor. Nangona kunjalo, xa ivalvu yokungenisa umoya isetyenziswa kwi-compressor yomoya eguquguqukayo yemagnethi esisigxina, kunokubakho ukungcangcazela kwevalvu yokungenisa umoya. Xa injini isebenza kwi-frequency ephantsi, ipleyiti yokujonga iya kungcangcazela, nto leyo ebangela ingxolo yokungenisa umoya. Ngoko ke, yintoni isizathu sokungcangcazela kwevalvu yokungenisa umoya ye-compressor yomoya eguquguqukayo yemagnethi esisigxina?

Izizathu zokungcangcazela kwevalvu yokungenisa yecompressor yomoya eguquguqukayo yemagnethi esisigxina:

Isizathu esiphambili sale meko sisipringi esiphantsi kwepleyiti yevalvu yevalvu yokungenisa umoya. Xa umthamo womoya wokungenisa umoya umncinci, ukuhamba komoya akuzinzanga kwaye amandla entwasahlobo makhulu, nto leyo eya kubangela ukuba ipleyiti yevalvu ingcangcazele. Emva kokutshintsha intwasahlobo, amandla entwasahlobo mancinci, nto leyo enokusombulula ezi ngxaki zingasentla.

Ngokomgaqo, xa ivalvu yokungenisa ivuliwe, ivalvu yokungenisa yecompressor yomoya iyavalwa, kwaye injini iqhuba injini ephambili ukuba ingasebenzi. Xa ivalvu ilayishiwe, ivalvu yokungenisa iyavuleka. Ngokwesiqhelo, umbhobho wegesi omkhulu kune-5mm ukhutshwa kwisigqubuthelo esiphezulu se-oyile-gas separator, kwaye ivalvu yokungenisa ilawulwa yiswitshi yevalvu yesolenoid (ngesiqhelo ivalvu yesolenoid iyavulwa). Xa ivalvu yesolenoid inikwe amandla, ivalvu yokungenisa engenamoya oxinzelelweyo iphefumlelwa ngokuzenzekelayo kwaye ivulwe, ivalvu yokungenisa iyalayishwa, kwaye icompressor yomoya iqala ukuvuthela. Xa ivalvu yesolenoid ikhutshwa amandla, umoya oxinzelelweyo ungena kwivalvu yokungenisa, uxinzelelo lomoya luphakamisa i-piston, ivalvu yokungenisa iyavalwa, kwaye ivalvu yokukhupha ivulwa.

Uxinzelelo lomoya lwahlulwe ngeendlela ezimbini, enye ingena kwivalvu yokukhupha umoya kwaye enye ingena kwicompressor. Ivalvu yokukhupha umoya inesixhobo sokulungisa ubungakanani bokukhupha umoya ukulawula uxinzelelo olukwibhareli yokwahlula. Uxinzelelo ngokubanzi lunokulungiswa lube yi-3 kg, uxinzelelo luyanda ngokujika ngewotshi, kwaye uxinzelelo luyancipha ngewotshi, kwaye i-nut elungisiweyo iyalungiswa.

Indlela yokulungisa ivolumu yomoya wevalvu yokulayisha, xa ukusetyenziswa kwegesi yendalo yomsebenzisi kungaphantsi komthamo wokukhupha umoya weyunithi olinganiselweyo, uxinzelelo kwinkqubo yenethiwekhi yombhobho yomsebenzisi luya kunyuka. Xa uxinzelelo lufikelela kwixabiso elimiselweyo loxinzelelo lokukhupha umoya, ivalvu yesolenoid iyacinywa, umthombo womoya uyanqunyulwa, kwaye ulawulo lungena kwivalvu edibeneyo yomlawuli wokungenisa umoya. Ipiston iyavalwa phantsi kwamandla entwasahlobo kwaye ivalvu yokukhupha umoya iyavuleka. Umoya ocinezelweyo kwisihluzi seoyile-gesi ubuyela kwindawo yokungena emoyeni, kwaye uxinzelelo luyehla luye kwixabiso elithile.

Ngeli xesha, ivalvu yoxinzelelo oluncinci ivaliwe, inethiwekhi yombhobho womsebenzisi yahlulwe kwiyunithi, kwaye iyunithi ikwimeko yokusebenza ngaphandle komthwalo. Njengoko uxinzelelo lwenethiwekhi yombhobho womsebenzisi luyehla kancinci ukuya kwixabiso elimiselweyo loxinzelelo lomthwalo, ivalvu yesolenoid ifumana amandla kwaye iqhagamshelwe kumthombo womoya wolawulo wevalvu edibeneyo kwisilawuli sokungenisa. Phantsi kwesenzo solu xinzelelo, i-piston ivuleka ngokuchasene namandla entwasahlobo, ngaxeshanye ivalvu yokukhupha umoya ivala, kwaye iyunithi iqalisa ukusebenza komthwalo.

Oku kungasentla sisizathu sokungcangcazela kwevalvu yokungenisa umoya yecompressor yomoya eguquguqukayo yemagnethi ehlala ihleli. Ivalvu yokungenisa isebenza kunye nevalvu yesolenoid, isenzi soxinzelelo, kunye nomlawuli we-microcomputer ukulawula iswitshi yesango lokungenisa umoya. Xa iyunithi iqala, ivalvu yokungenisa umoya ivaliwe, edlala indima yohlengahlengiso lokuthontelana komoya, ukuze icompressor iqale kumthwalo omncinci; xa icompressor yomoya isebenza kumthwalo opheleleyo, ivalvu yokungenisa umoya ivuliwe ngokupheleleyo; xa icompressor yomoya isebenza ngaphandle komthwalo, ivalvu yokungenisa umoya ivaliwe kwaye ioyile negesi zahlulwe. Uxinzelelo olukwisahluli lukhutshwa luye kwi-0.25-0.3MPa ukuqinisekisa uxinzelelo lonikezelo lweoyile lwenjini ephambili; xa umatshini uvaliwe, ivalvu yokungenisa umoya ivaliwe ukuthintela igesi kwisahluli seoyile-gesi ukuba ingabuyeli umva, okubangela ukuba i-rotor ibuyele umva kwaye kwenzeke ukufakwa kweoyile kwisango lokungenisa umoya.

Ixesha lokuthumela: Agasti-01-2023